RF/mmW and 5G Production Wafer Test

The promise of 5G is significantly greater mobile speeds for real-time connectivity for mission-critical applications. 5G has the potential to connect billions of IoT devices with a wide variety of speed and data volume requirements.

The much-anticipated ramp for 5G deployment is underway in multiple countries around the world bringing with it a host of new challenges in RF Test. New Antenna-in-Package (AiP) and Intermediate Frequency (IF) devices with arrays of mm-Wave signals are pushing the upper limits of what can be supported with today’s technology. Higher performance front end modules must provide higher isolation to an increasingly crowded spectrum of signals. Both are driving new test solutions as this technology continues to ramp. In both engineering characterization and production, the challenge of testing 5G devices is how to test a broad spectrum including higher frequencies while maintaining high throughput. With the significant increase in test content that 5G brings, FormFactor can provide fast, accurate measurements on 5G devices at sustainable COO.

A Deep Portfolio of RF Solutions

From engineering to production, FormFactor has embraced this challenge, and is participating in the first wave of 5G devices. One major objective of this new standard is to reduce the cost per bit (data cost) compared to 4G LTE by operating in a wider spectrum of bands in the mmWave region of RF signals for mobile networks. The main challenges associated with 5G device testing in the mmWave region are:

· Managing the high-fidelity signal requirements of mmWave.

· Handling the large number of RF channels due to phased-array antennas for beam forming.

· Significantly longer test time due to the increased number of frequencies and test conditions, where test automation is essential to ensure fast time to market.

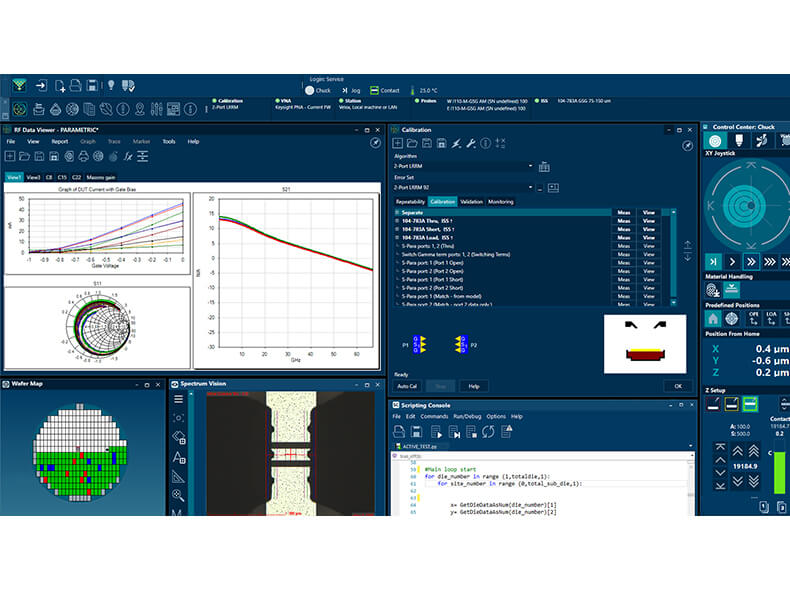

To meet these demands in the engineering lab, FormFactor has expanded its Contact Intelligence™ technology and introduced the Autonomous RF Measurement Assistant, a combination of hardware and software components added to FormFactor’s probe stations, enabling true hands-free operation over multiple temperatures.

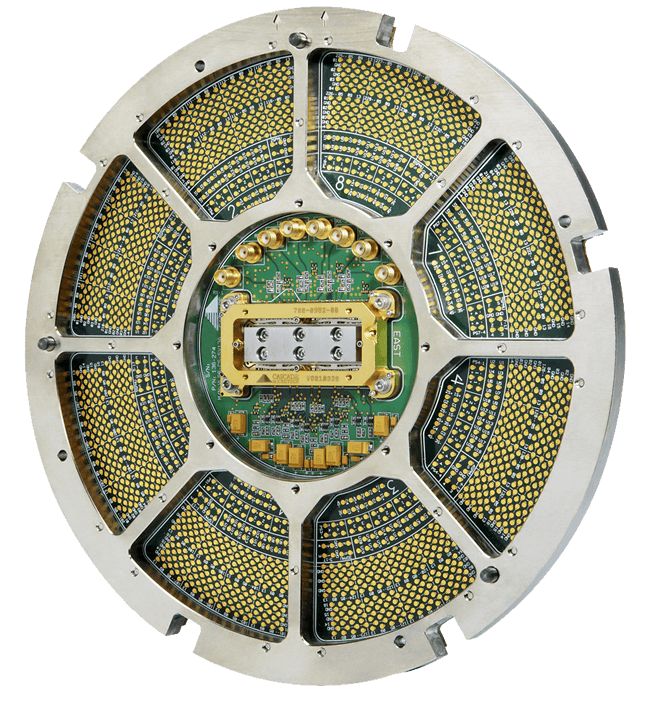

For production testing, we’ve responded with an expanded Pyramid portfolio to enable sub-6 GHz to 80+ GHz testing in multi-site configurations for the lowest cost of test. Our Pyramid probe cards utilize membrane probe technology which offers ultra-low inductance within microns of and superior signal integrity, enabling test capability of 80+ GHz.

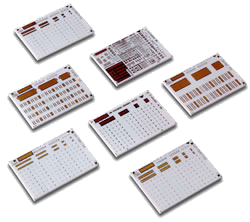

Our long experience supporting RF applications includes deep centers of expertise in RF simulation, calibration, and general performance diagnosis. That experience has allowed us to bring to market new RF wafer probe solutions with the highest parallelism available, lowering production test costs and providing superior RF test capability.

5G Production Challenges

5G applications using frequency range 2 (FR2) from 24-54GHz have shattered previous limitations on the number of mmWave lines to be tested with a single chip having as many as 38 lines in this range and potentially hundreds for multi-DUT testing.

In support of today’s high density mmWave applications, the Pyramid P2000 supports over 200+ mmWave lines with a high-density RF interface and 50 mm of active probe face for higher parallelism test enabling test parallelism of x8 for 5G AiP type devices. The expanded high frequency PCB toolbox now includes RF switches, dividers, high density connectors and other application specific tools to maximize test cell use.

FormFactor is a leader in supplying 5G production solutions with hundreds of probe cards shipped to leading edge customers. Bringing 5G to market requires an array of supporting tools to ensure the end products meet expectations all the while keeping price/performance as low as possible.

Supporting 5G Applications

The 5G revolution is underway with promises of higher bandwidth and faster data communication. With it comes new test challenges for higher frequency, better isolation, and far more mmWave signals than previous devices.