Cold Technology

is Heating Up

The use of on-wafer superconducting materials, other novel materials and traditional semiconductors at cryogenic temperatures (below about 123K, or -150°C) has risen markedly in recent years.

Inventive new sensors take advantage of unique material properties at very low temperatures to detect a wide variety of physical phenomena such as infrared radiation, magnetic fields, x-rays, and more, for application in many fields such as health care, defense, industrial automation, and astronomy.

FormFactor has played an active role in bringing these technologies to market, producing high-performance cryogenic and vacuum probe systems since 2000 with unmatched automation capabilities to support activities from academic research to industry production.

Cold Image Sensors See Heat Best

High-performance thermal imaging is widely used today in surveillance/security, night vision, remote sensing, meteorology, military threat and target detection, body heat analysis, astronomy, and more. These systems use FPAs (focal plane arrays) based on cooled IR sensors. Cryogenic environments reduce thermal noise so that these detector arrays can deliver improved resolution and sensitivity.

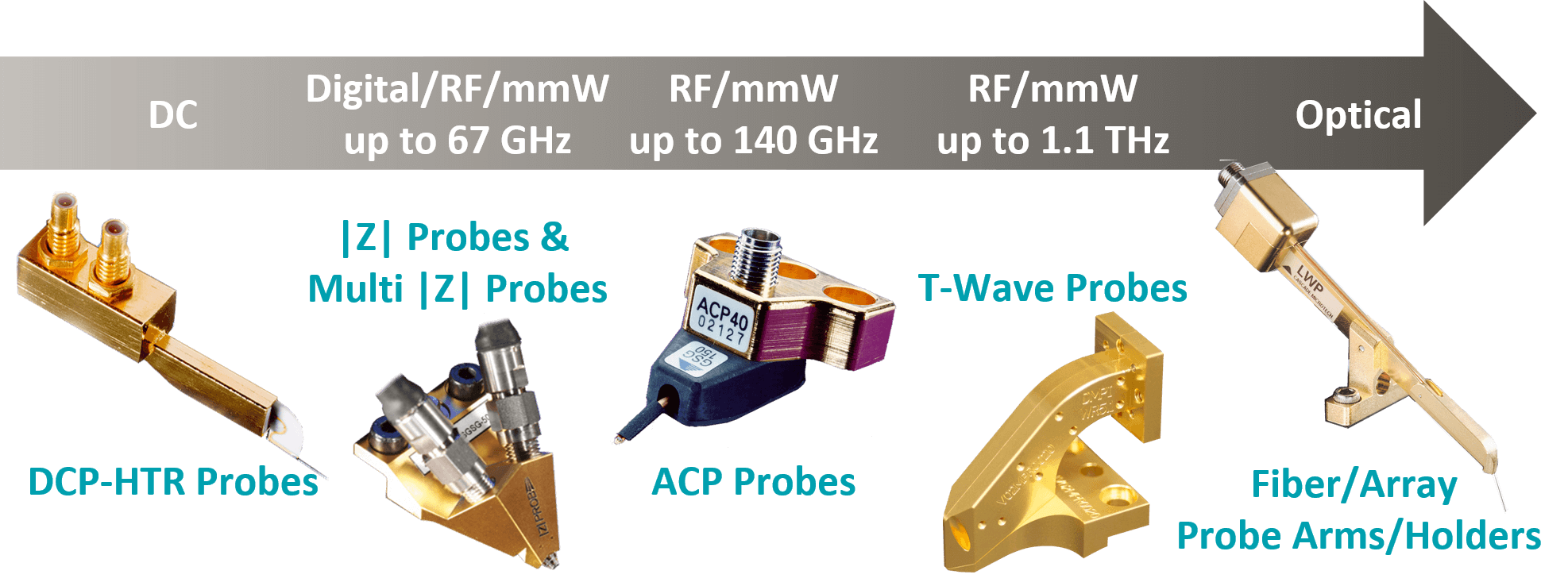

Cooled IR sensors are built from different materials to target various wavelength ranges from the near infrared (NIR) through long wave infrared (LWIR), including silicon, numerous III-V compounds (InGaAs, InSb, InAsSb, InAs/GaSb, etc.), often designed as quantum well photo detectors, MCT (mercury cadmium telluride), and superconducting photon detector technologies including YBCuO, GdBO3, MgB2, and more. Testing these low-temperature technologies on wafer requires a cryogenic probe system.

Cryogenic Challenges Require Specialized Probe Systems

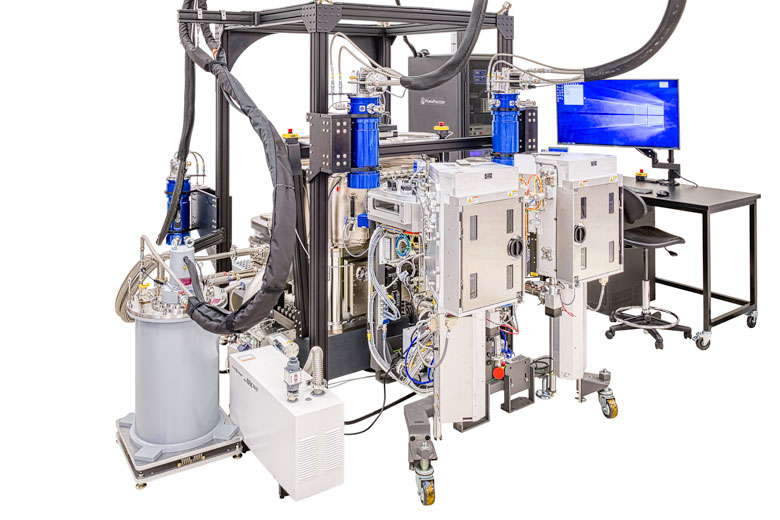

The cryogenic test environment begins with a vacuum chamber to provide a suitably sealed and evacuated environment. A cryostat using liquid nitrogen or liquid helium, or other means of refrigeration, lowers temperatures to 77K or below; resistive heaters, cryogenic grade temperature sensors and a temperature controller complete the temperature regulation. Signal feedthroughs, optics for cameras, and probe positioner controls all require special considerations for access to the extreme vacuum/cold environment. Safety, vibration, and sample mounting also present new challenges for vacuum/cryogenic conditions. Condensation and particulates are also unique complications when temperatures drop. Even the probes must be designed for use at cryogenic conditions. Finally, although many solutions are available for single small diced samples with just a few signals, process and product qualification requires a higher class of tools. High volume testing demands a large chamber for full wafer samples, multi-channel cryogenic probe cards, a software-controlled wafer stage for step-and-repeat testing across the wafer surface, and other capabilities to maximize test throughput.

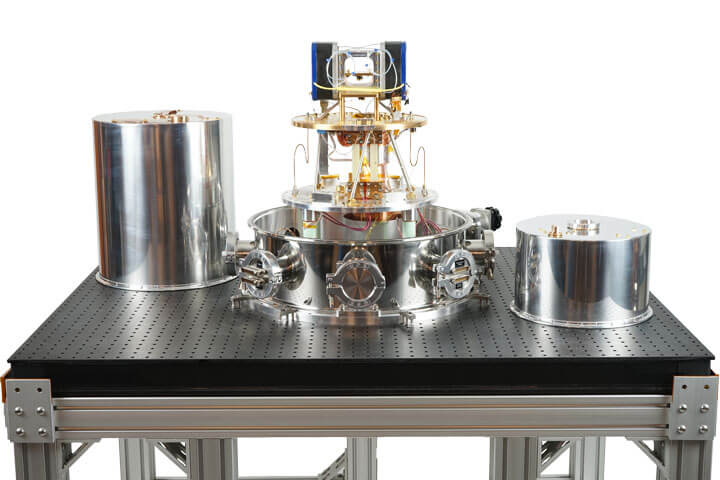

Conducting High-Accuracy Measurements at True 4 K Cryogenic Temperatures

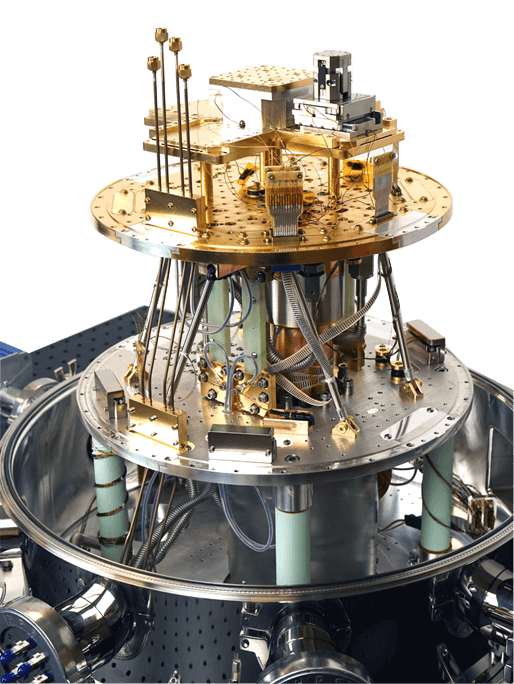

The HPD cryogenic chip-scale probe stations tackle problems like long turnaround times, high noise, and low signal capabilities. By employing world class technology, superior cryogenic probing knowledge, and test application engineering expertise, these systems enable accurate measurements at ultra-low temperatures. With a range of integrated measurement solutions enabling true 4 K sample temperature operation, FormFactor’s HPD chip-scale probe stations can be customized to fit your sampling needs for whatever signal (DC, RF, FO) you need to get to your sample.

With advanced features to reduce mechanical vibration, block stray light from reaching the sample, and shield stray magnetic field, the systems are designed to eliminate noise and ensure temperature stability.

Optionally, choose a system with a larger stage design and the ability to incorporate our scanning squid microscope. All of our systems offer a broad array of optional features to ensure the customized system will meet your probing needs today and in the future.

IQ2000 Cryogenic Probe Station

High Throughput Cryogenic Systems Lead the Industry

FormFactor is ahead of the pack for high-throughput cryogenic wafer test, with this unmatched combination of powerful features:

• Step-and-repeat automation with programmable, motorized XYZΘ stage.

• Automatic camera-based alignment adjustments at each step.

• Up to 8 easily positioned and very stable cryogenic probes for DC, RF, and optical signals – and probe cards for even higher signal count.

• Sample sizes from fragments up to full 200mm wafers (300mm option available).

• Wafer exchange without disrupting probes or probe cards.

• Programmable, motorized positioning of multiple black-body radiation sources, microscopes, and other equipment

• High test throughput enables our customers to move from lab concepts to device characterization to design debug to high-volume engineering/production test. FormFactor’s lineup includes multiple size and automation levels, and flexible/customizable configurations.

|

|

|

Sophisticated Cryogenic Tools Simplify Cryogenic Test

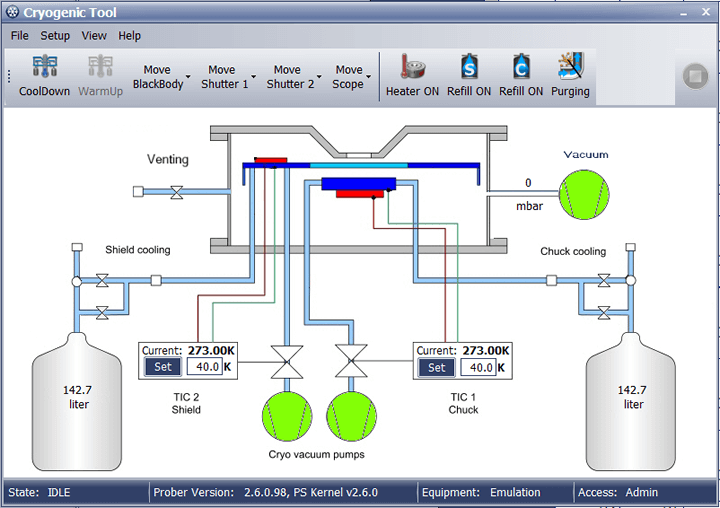

The Cryogenic Tool is a Velox application that enables precise on-wafer measurements in extreme environments by controlling vacuum pump and coolant parameters. It has been developed for cryogenic probe systems that enable testing of cooled IR sensors and cutting-edge technologies that require cryogenic temperatures. It supports auxiliary functions like automatic refill of the liquid nitrogen dewars and automated swapping of the IR radiation sources (blackbodies).

• Graphical interface of vacuum/cryogenic probe station

• Real-time display of process parameters

• Wizard-guided operation

• Semi-automated process tools