Related Products

FormFactor offers a full spectrum of proven test and measurement technologies and unmatched expertise in how to best integrate them from lab to fab.

Flicker noise and IC performance – low noise with high impact.

Flicker noise is a key factor in electronics, impacting device size and more. Flicker noise can cause background noise in smartphones and other communication devices, logic errors in low-voltage digital circuits, accuracy errors in A/D circuits, bit errors in Flash memory, and distortion in image sensors. As a key limiter of electronic device and circuit performance, this noise must be managed through optimizing materials, design and manufacturing process. Accurately measuring low frequency noise (LFN) at wafer level has become even more critical for advanced high-speed, low power technologies found in newer 5G devices and nanoscale transistors.

Wafer level LFN measurements include flicker noise (1/f), random telegraph signal noise (RTN or RTS), and phase noise. The application needs for wafer-level LFN measurements include:

1. Process design kit development

Semiconductor device foundries enable fabless design centers to design components such as transceivers for mobile phones, frequency synthesizers, analog-to-digital converters and much more. To make this possible, foundries must provide Process Design Kits (PDK’s) with simulation models that include noise effects on transistors (BJT, CMOS, etc.) and resistors, including LFN across all possible bias currents, temperatures and device geometries.

2. Manufacturing statistical process control and reliability

Device manufacturers can use noise measurements across their wafers as an early indicator of device reliability. Those devices that exhibit more noise are likely to fail sooner. Furthermore, for circuit applications where noise is a critical parameter, wafer level measurements may be used to track the evolution of noise performance across days, weeks and months of manufacturing.

Low frequency noise testing has historically been one of the most difficult measurements at wafer level because of unwanted environment noise from inside and outside a probe station. This can significantly reduce the signal-to-noise ratio (SNR), resulting in decreased accuracy, corrupted high-performance device data, and slow measurement times. Data collection cycles required for most standard device models can take days or weeks to complete. Typically, this would be 30 minutes to measure frequencies down to 1 Hz on a single device, multiplied by 3-5 bias levels, over 4-6 different temperatures, for each of the 15-30 test devices on a wafer.

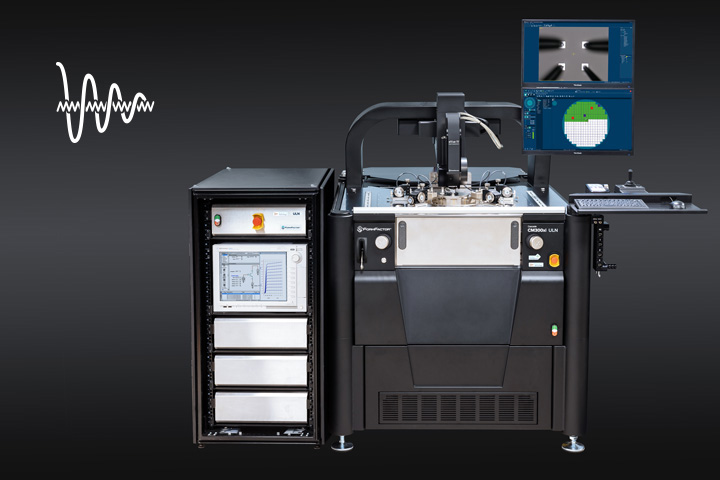

FormFactor’s new CM300xi-ULN probe station directly addresses these challenges with its new extremely low noise floor level (-190dBVrms/rtHz spectral noise), a range of product and service enhancements to make highly accurate noise measurements, and automated features to significantly increase on-wafer test throughput.

PureLine™ 3 TechnologyFirst automated probe station to achieve -190dB spectral noise* |

|

|

Plug In and GoIntegrated TestCell Power Management provides fully managed and filtered AC power to the entire system, prober and instruments |

|

Autonomous 24/7 OperationUp to 4x faster flicker noise thermal testing on 30 μm pads |

|

Reduce Setup Time and CostsExclusive low noise site survey, and system verification services |

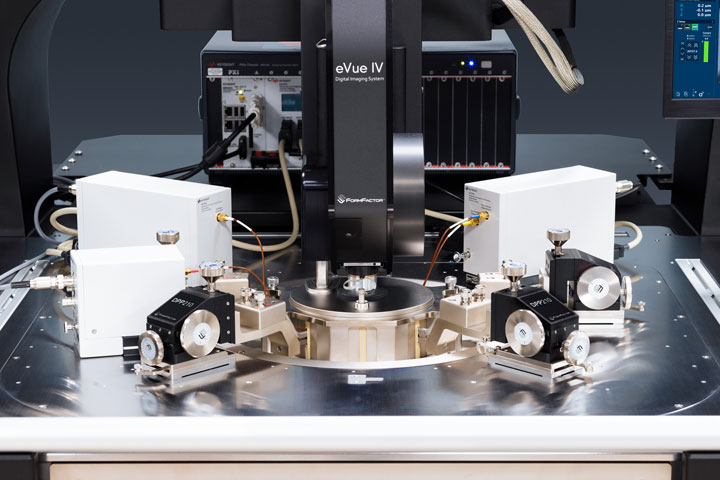

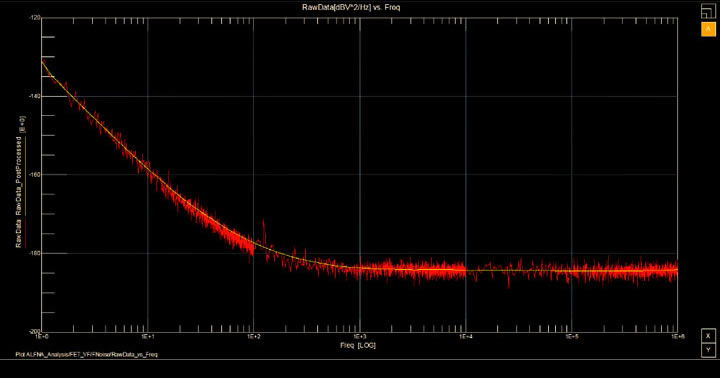

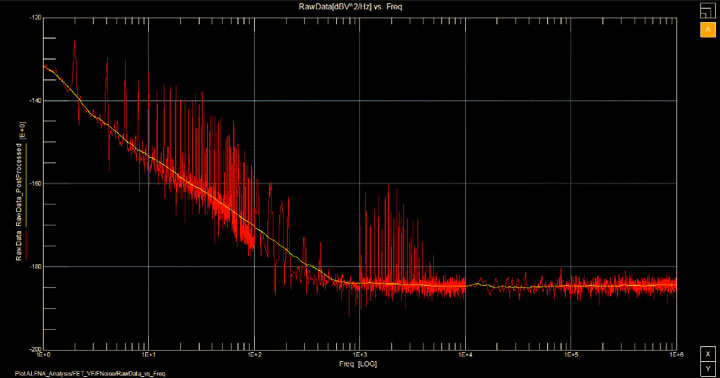

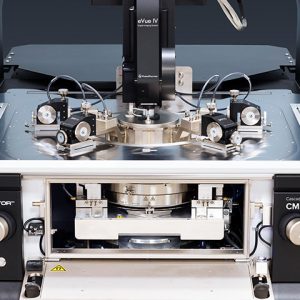

To demonstrate the significant improvements of PureLine 3 technology, the following data provides a comparison of “chamber” noise between two 300 mm probe stations as seen by a DC probe inside the probe station at the DUT level. Figure 1 shows the physical test setup using Keysight A-LNFA flicker noise system (E4727A), and DCP-HTR probes. In Figure 2, data is shown using the new CM300xi-ULN probing system, and in Figure 3, a standard CM300xi-F model. With the same test setup on the two probe stations, the significantly improved clean noise floor of the new ULN system is clearly observed.

Figure 1: Test setup for chamber noise data using Keysight E4727A (A-LFNA). 3 DCP-HTR probes connected to drain, source, gate terminals. All probes inside the probe station MicroChamber shielding environment.

Figure 2: CM300xi-ULN chamber noise graph, 1Hz to 1MHz (VAMP LF), 32 point averaging, 1600 points/decade, Rload and Rsource = 0 ohm, using Keysight E4727A (A-LFNA). Y-axis scale for Power -140 to -200 dB.

Figure 3: Alternative system chamber noise graph, same test conditions and display scales as figures 2 and 3.

PureLine™ generation 3 technology comprises an extensive collection of FormFactor technologies that together provide an effectively noise-free environment around the device under test (DUT). Compared with previous generations, the new PureLine 3 enables up to 32x improvement in spectral noise performance for fast and highly accurate device measurements on-wafer.

Precise flicker, RTN, and phase noise measurements for next generation materials, package interconnects, transistors, and IC’s can now be done simply and automatically for faster time to data. PureLine 3 technology integrated into the CM300xi-ULN (Ultra Low Noise) 300 mm probing system includes:

|

ULN MicroChamber™

This newly-enhanced critical probing environment directly surrounds the DUT and wafer chuck to ensure a complete EMI / RFI shielded area like a Faraday cage. In addition, the ULN MicroChamber provides the dark and dry environment essential for measuring light sensitive transistors and devices at negative temperatures (<= -60°C) with frost-free operation. |

|

ULN Power Conditioning Unit

The patented PureLine 3 technology in the ULN Power Conditioning Unit (PCU) provides clean, filtered AC power to the entire probe system and all instruments, and forms the foundation for the Test Cell Power Management (TCPM) system which eliminates ground-loops between probe station and instruments that cause significant low frequency noise. |

|

ULN Thermal Filtering Module

The ULN Thermal Filtering Module is vital for enabling ultra-low noise probing at temperature, reducing harmful noise generated by external thermal control systems by up to 30dB above 1Mhz. |

|

ULN Single Point Grounding, and Cabling System

Each ULN system also includes a single point grounding system for all prober accessories, with low resistance grounding connections for reduced “antenna effect” injection of unwanted RF noise into the measurement path. |

|

ULN SMU Filtering Modules for Accurate PLL Phase Noise

For highly accurate phase noise measurements of devices such as Phase Lock Loop circuits (PLL) and Voltage Controlled Oscillators (VCO), newly developed DC filter modules for Source Measure Units (SMU) can be used to provide ultra-quiet / clean DC supply voltage. The high-performance DC SMU filtering modules provide up to 100dB attenuation (50Hz to 80Mhz) with 100mA max DC current handling. Each SMU filter module supports one channel, and multiple modules can together provide multi-channel clean power. |

|

ULN Contact Intelligence modules

New ULN Contact Intelligence™ modules (with 1, 2, or 4 motorized positioners), with PureLine 3 noise reduction, make the CM300xi-ULN the world’s first probe station to achieve autonomous flicker noise thermal testing on 30 μm pads over multiple temperatures for complete hands-free 24/7 operation. |

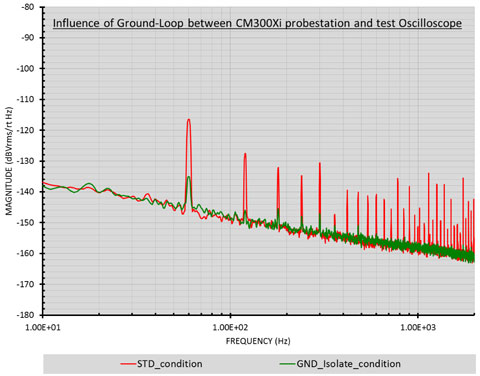

Noise from Test Cell Interconnects

A traditional measurement Test Cell includes test software, a few instruments, probe station, thermal system, and related measurement accessories (cables, on-wafer probes) to collect test data. Even when all the equipment parts are well-designed (low noise, high quality, good EMI/RFI shielding), joining them together forms long AC power ground loops. When nearby magnetic fields pass through these ground loops, they are converted into small electrical signals resulting in unwanted power line frequency noise with multiple harmonics, as shown in the following Test Cell example, with unwanted noise (red trace) vs ground isolated condition (green trace).

Figure 4: Measurement of chuck noise with Keysight Oscilloscope. The STD condition with ground-loop, shows more than 30 power line fundamental and harmonics noise spectrums. With the improved GRD isolated condition, the power line fundamental and harmonics noise spectrums are dramatically reduced. (Note: 60Hz power line spectrum is only -20dB (= 1/10) reduced.)

For small applications, using simple battery power can eliminate unwanted power line frequency noise, and an isolation transformer can be used where AC power is needed.

However, this technique has serious limitations when scaling up to support the size and power needs of a Test Cell with a thermal probe station. Among these are high cost, large physical size, complex cabling, safety issues, and increased magnetic field generation.

To address and solve this problem, FormFactor developed a new Test Cell Power Management system using PureLine 3 patented technology. The CM300xi-ULN probing system is now the world’s first probe station with integrated Test Cell Power Management to provide fully managed and filtered AC power to the entire system, prober and instruments and eliminate ground-loop induced Test Cell noise.

Cost savings in the lab

The CM300xi-ULN takes the mystery and complexity out of low noise Test Cell optimization. Just plug it in and go, and let lab engineers focus on gathering important device data instead of troubleshooting grounding problems that corrupt measurements.

The cost savings can be significant, eliminating up to 6-10 weeks of wasted engineering time and 2-3 months of delayed product testing. And with high throughput test automation, test labs can focus on getting accurate data faster to make more efficient technology business data decisions and ensure the right products are delivered to market quickly.

Picking the best location

High performance flicker noise or phase noise Test Cell data can be degraded by installing the Test Cells in a bad location. Finding a good location can be a time consuming and difficult task, requiring specialized measurement equipment and tools such as accelerometers, oscilloscopes, high performance low noise amplifiers (LNA’s), test software, magnetic flux probes, and more. Often, it requires specific applications knowledge on how to identify noise signatures and troubleshoot installation location issues.

New services that reduce deployment costs

Customer requests have led to another first for the CM300xi-ULN probing system: the first probe station with customer low-noise site surveys and low-noise installation verification.

The CM300xi-ULN’s facility planning guide has a list of the standard and unique system requirements for the probing system. For interested customers, a new ULN Site Survey service is available from FormFactor. And to ensure customer satisfaction after the system installation is complete, a new ULN System Verification is performed demonstrating key specifications and performance tied to the standard product datasheet.

A site survey performed by a FormFactor factory-trained engineer will determine the best location to install the ULN system. Customers will typically suggest 2 or 3 locations, and a survey will be done at each to measure and compare four critical noise sources:

A ULN System Verification is performed after every CM300xi- ULN probe station is installed. This specialized service uses FormFactor supplied test equipment, and includes a 50+ point checklist. Key product specification parameters are measured such as Spectral Noise Density (dBVrms/√Hz, 1Hz to 20MHz), and AC chuck noise (mV p-p, DC to 2.5GHz).

The DCP-HTR Probe

The DCP-HTR probe delivers femtoampere-level measurement capability from -65°C to 300°C for advanced characterization and reliability testing. Its unique design offers superior guarding and shielding overtemperature, overcoming the high-temperature performance limitations of standard coaxial needles. The optional small diameter probe tips can probe pads as small as 30 x 30 μm.

DCP 100 Series Probe

The DCP100 probe delivers the measurement accuracy needed for advanced on-wafer process, device characterization and reliability testing. With superior guarding and shielding, these probes overcome the performance limitations of non-coaxial needle probes. Probe tips are available in 1, 3 and 10 μm diameters. Learn more about the features and applications of the DCP100.