Apollo

Designed for fine-pitch flip-chip applications with high current carrying capability - copper pillar and solder bumps

Designed for fine-pitch flip-chip applications with high current carrying capability - copper pillar and solder bumps

Looking for customer support? Ready to learn more about our products and services?

Contact Sales TodayReceive product updates and event notifications

Subscribe to Our Newsletter

To meet consumer demand for portable computing products that are attractively priced, consume less power and offer “always on” connectivity, the semiconductor industry has stepped up with advances in process and packaging technologies.

While leading-edge semiconductor technologies deliver important advantages for low-cost and low-power applications, they present significant challenges for wafer testing. For example, wafer test faces stringent electrical performance requirements, and continued scaling in pad pitch, density and probe force, combine to lower cost and cycle-time trajectories to meet the demands of consumer-driven end markets.

FormFactor addresses these challenges with the industry’s broadest portfolio of non-memory wafer test probe cards offering high parallelism for greater throughput, stable contact resistance for optimal test yield, and superior contact precision. Through on-going investments in its technology, the company can quickly scale to meet customers’ future technical roadmap requirements for performance and geometry shrinks. FormFactor delivers a suite of advanced MEMS, vertical and cantilever probe cards.

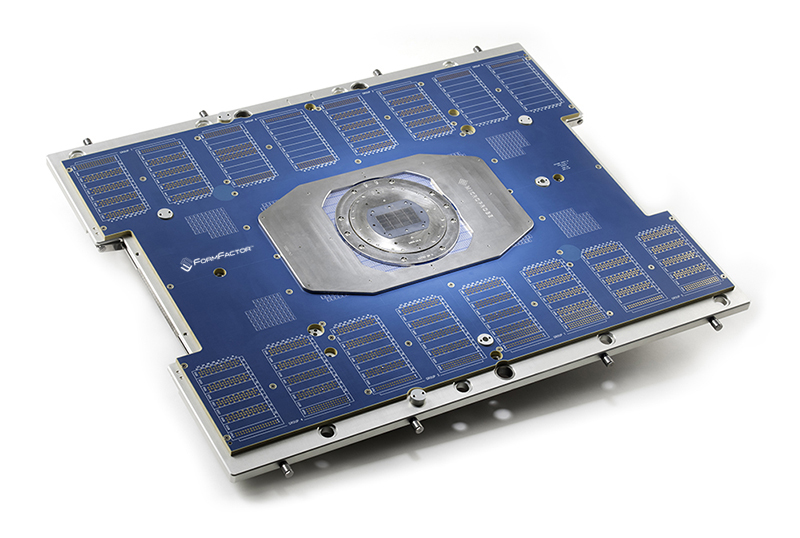

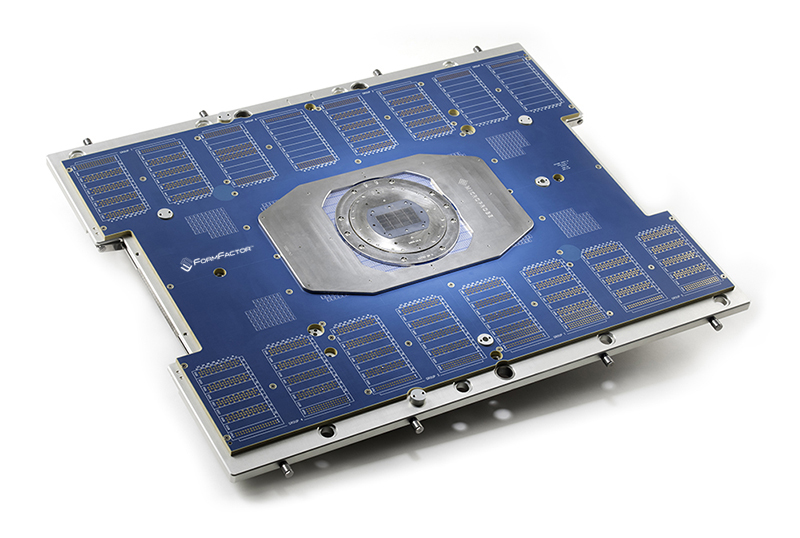

Apollo vertical probe cards are suitable for area-array and perimeter-layout probing applications, including both flip chip and pre-bump or aluminum pad application. Apollo is the industry-leading flip chip probe card of choice for graphics processors, game console microprocessors, and automotive microcontrollers. Leveraging proprietary manufacturing technology, Apollo delivers excellent reliability and quality for multi-DUT testing, and technology scalability to address a broad range of testing requirements.

Apollo is the probe of choice for baseband and application processors in mobile devices. Valued for its “Right First Time” reliability, Apollo is known for its unique electrical/ mechanical design/modeling capability to ensure optimal yield in multi-site testing environments.

A variety of probe options are available – from traditional Cobra-style wires to fine-pitch vertical MEMS, and space transformer options. Collectively, they’re designed to ensure lowest cost of test production configuration for mobile device testing. For Consumer ICs, Apollo is the industry-leading flip-chip bump probing technology for multi-core processors used in game consoles like the Xbox and PlayStations. Already the industry-leading bump/Cu pillar probing technology for mobile phone processor SoCs, Apollo is also a popular probe choice for automotive infotainment processors.

• Broad range of vertical and vertical MEMS probe options, scalable to 80 um pitch

• Proprietary manufacturing technology for reduced Cres and improved wafer yield

• Superior current-carrying capability for enhanced production uptime and quick time-to-market

• Minimum grid-array pitch of 80 µm (or Minimum grid-array pitch of 135µm)

• Supports high multi-site testing (X8–X16) with ultra-high pin count (20 – 30k pins)

• Ultra low-force vertical MEMS probe options for Cu pillar probing, 1.5 to 2.5 g/probe

• Flip-chip bump or Cu Pillar probing

• High current carrying option, up to 1A/probe

• Ultra-low force to allow high-temperature probing on solder-capped Cu pillars. <2 g/probe in production, demonstrated minimum solder cap disturbance post-probing to ensure back-end packaging reliability

Receive product updates and event notifications

Subscribe to Our Newsletter