Autonomous Silicon Photonics

Autonomous SiPh wafer probing featuring Contact Intelligence

Autonomous SiPh wafer probing featuring Contact Intelligence

Looking for customer support? Ready to learn more about our products and services?

Contact Sales TodayReceive product updates and event notifications

Subscribe to Our Newsletter

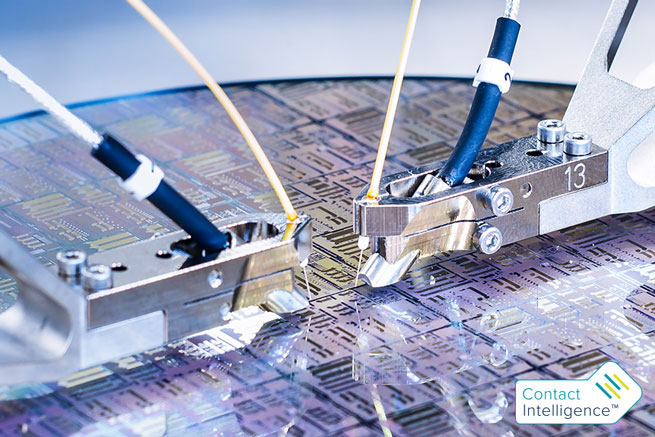

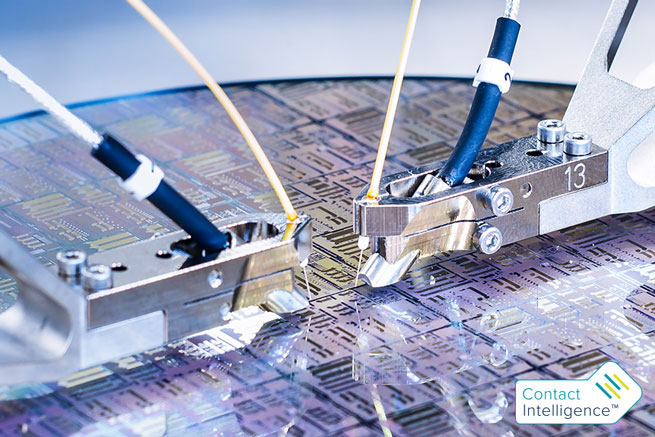

Flexible Silicon Photonics Probing Solution for Vertical and Edge Coupling

FormFactor’s Autonomous Silicon Photonics Measurement Assistant sets the industry-standard in wafer and die-level silicon photonics probing. This highly flexible solution provides a multitude of testing technologies from single fibers to arrays and from vertical coupling to edge coupling. With the new revolutionary OptoVue for advanced calibrations, intelligent machine vision algorithms and the exclusive SiPh TopHat for dark, shielded and frost-free environment, the system enables hands-free autonomous calibration and re-calibration at multiple temperatures. This enables faster time to more accurate measurements and reduced cost of test.

The use of single optical fibers and fiber arrays as probes to couple light into and out of a wafer for both surface and edge coupling creates many challenges that FormFactor manages through its Contact Intelligence technology. Unlike electrical testing, optical testing uses fibers and fiber arrays that do not contact their corresponding ‘pads’ known as grating couplers or facets on the wafer surface and edge, respectively. Instead, fibers need to be articulated relative to the couplers and facets to find the position of maximum optical power transfer.

Setting the initial position of the fiber or array tips relative to the gratings and facets and then optimizing their position is accomplished through unique automated techniques developed by FormFactor engineers. Using advanced image processing and specially developed algorithms, Z height setting, fiber-to-facet gap, as well as a suite of automated calibrations of the positioning solution to the probe station are available.

FormFactor has also implemented a Z displacement sensing technology that enables precise sub-micron level placement accuracy of the fibers and arrays when stepping die-to-die. These automated optical capabilities can also be combined with programmable DC and RF positioning technology to create a truly automated Optical-Optical, Optical-Electrical, and Optical-Electrical-Optical test platform.

For optical applications, Contact Intelligence reduces what used to take days, weeks or months to a matter of minutes while offering flexibility in a dynamic engineering environment and a stable repeatable environment for production.

The Autonomous Silicon Photonics Measurement Assistant is available for the following 200 mm and 300 mm probe stations: CM300xi-SiPh and SUMMIT200.

Autonomous Silicon Photonics Measurement Assistant

FormFactor's Autonomous Silicon Photonics Measurement Assistant enables and optimizes silicon photonics coupling. The use of single optical fibers and fiber arrays as probes to couple light into and out of a wafer surface creates many challenges that FormFactor manages through its Contact Intelligence technology.

Solving the Data Center Energy Crisis with Silicon Photonics | Dr. Choon Beng Sia

A deluge of business data flows into corporate data centers each day, faster than anyone can sort through it. At the same time, consumers are communicating, browsing, buying, sharing, and searching—creating their own enormous trails of data and an incredible energy demand at data centers. FormFactor’s Dr Choon Beng Sia presents a paper on the application of Silicon Photonics (SiPh) devices, how these new devices can help lower energy consumption in data centers, why accurate and reliable wafer-level photonics test are needed, and how FormFactor is helping to address the challenges of testing SiPh devices.

imec’s Silicon Photonics Research and Manufacturing Program

See how our customer imec is using our CM300 to enable their development of silicon photonics solutions

SourceOne – Certified Pre-Owned Equipment

You want the best price-performance ratio for your wafer probe station? With our Certified Used Equipment we have an attractive option for you.

SourceOne – Factory Refurbishment Program

Extend the use of your probe station for up to another 15 years with our Factory Refurbishment Program.

SourceOne – Trade In / Buy Back Program

We'll take your probe station back for a credit note.

Receive product updates and event notifications

Subscribe to Our Newsletter