Computing, Data Centers and Quantum — from Lab to Fab

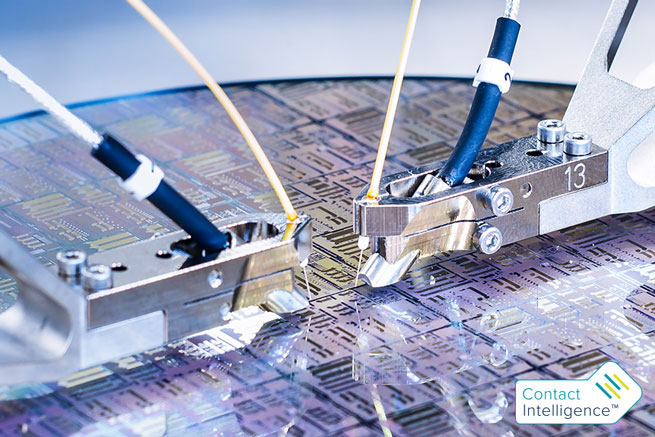

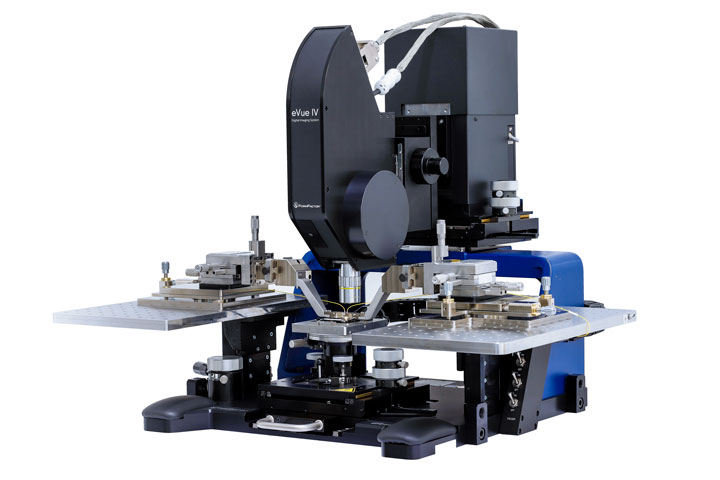

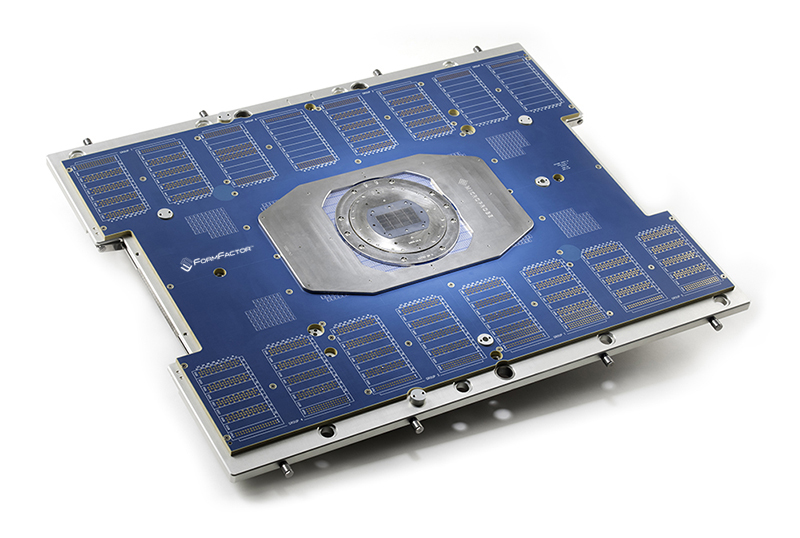

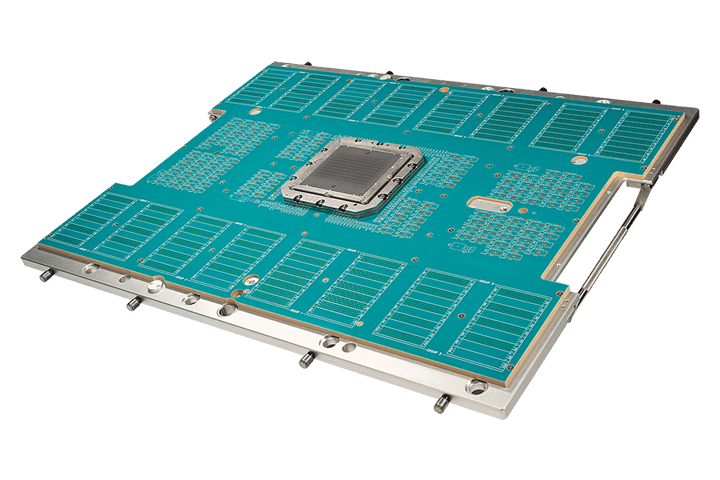

To meet the world’s persistent demand for high data throughput at minimum energy levels, the semiconductor industry has aggressively pursued the development of new technologies and the refinement of existing ones for processing and storing data. FormFactor is deeply involved in this development, as virtually all these devices must be tested at the wafer-level as they move from the lab to fab.

Integrated circuits (ICs) with feature sizes as small as 3 nm promise to combine high throughput with optimal energy efficiency in high performance computing (HPC) settings, like AI and data centers. We’re already delivering the industry’s most-trusted, advanced wafer probing techniques for both R&D and high-volume production of leading-edge CMOS technologies.

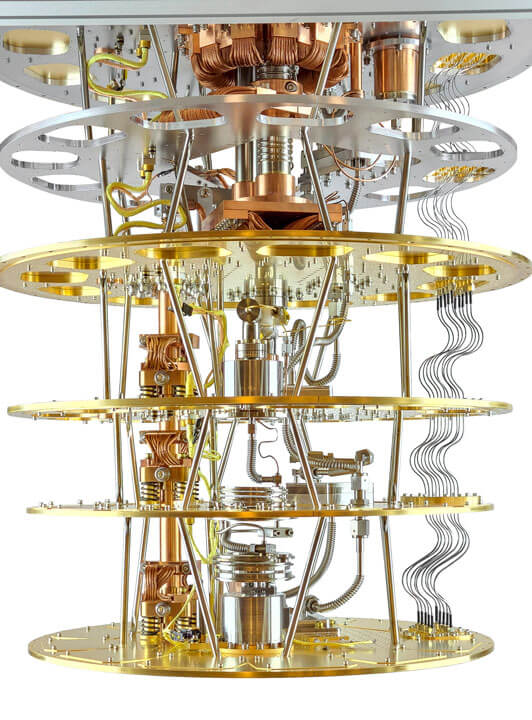

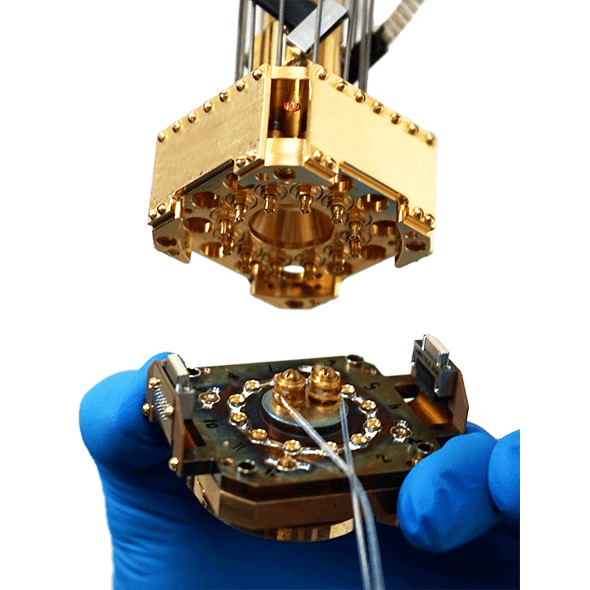

Quantum computing, once only theoretical, is moving steadily toward practical realization. Quantum devices operate at extremely low temperatures provided by our cryogenic probing systems.

FormFactor enables the data generation industry from lab to fab. As a leader in test and measurement our products and expertise are used in the following applications:

| Research / Development |

High Volume Engineering |

Niche Production |

High Volume Manufacturing |

|

|---|---|---|---|---|

| Quantum Computing | ||||

| Silicon Photonics | ||||

| Advanced Node | ||||

| AI Processors | ||||

| CPU / GPU / Logic | ||||

| Memory |

- Quantum Computing

- Research / Development

- High Volume Engineering

- Niche Production

- High Volume Manufacturing

- Silicon Photonics

- Research / Development

- High Volume Engineering

- Niche Production

- High Volume Manufacturing

- Advanced Node

- Research / Development

- High Volume Engineering

- Niche Production

- High Volume Manufacturing

- AI Processors

- Research / Development

- High Volume Engineering

- Niche Production

- High Volume Manufacturing

- CPU / GPU / Logic

- Research / Development

- High Volume Engineering

- Niche Production

- High Volume Manufacturing

- Memory

- Research / Development

- High Volume Engineering

- Niche Production

- High Volume Manufacturing

What's New

-

FormFactor Introduces Rapid Cooling Probe System for Quantum Device Testing

The IQ2000™ Cryogenic Chip Scale Probe System tests 10X more devices at 4 Kelvin

Published in Press Releases

-

FormFactor Named One of THE BEST Suppliers in the Semiconductor Industry for Tenth Consecutive Year

FormFactor receives a five-star rating in Annual TechInsights VLSI research customer satisfaction survey.

Published in Press Releases

-

Silicon Photonics (SiPh) Moving to Production

Learn about the ongoing development that is advancing photonics testing towards broad volume production.

Published in Blog

Quantum/Superconducting

Quantum computers stand poised to deliver dramatic breakthroughs in any number of scientific and engineering fields. Personalized drugs, pinpoint weather predictions, better batteries and super-secure encryption all fall within the realm of possibility, along with many other applications.

In parallel, another category of machines called superconducting computers promises to elevate conventional computing to the so-called exascale level, where they will deliver formidable processing speed at only one tenth the power of present technology.

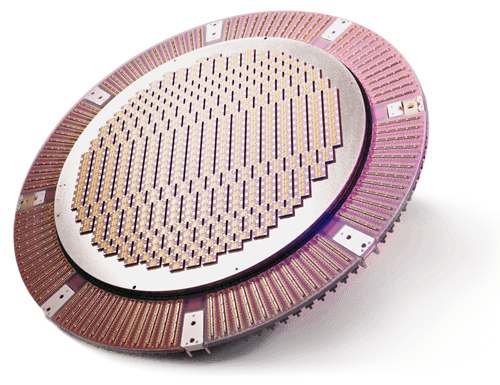

Both quantum and superconducting computers share a common requirement on their journey from the lab to fabrication: they can only function at ultra-low temperatures approaching absolute zero. FormFactor has taken aggressive steps to address this challenge by providing cryogenic environment systems, offering a suite of products including sub-10 mK dilution refrigerators, sub-100 mK cryostats, cryogenic chip-scale and wafer-scale probers, engineering probes, and probe cards.

Learn about cryogenic test applicationsSilicon Photonics

Silicon photonics (SiPh) holds the potential for spectacular gains in speed and power efficiency. The first wave of the SiPh revolution stands poised to roll over data centers around the world with optical interconnects that breach the self-heating barriers set by copper wire. Bandwidths of a terabit per second now come within practical reach. Additionally, new applications such as glucose monitoring and blood typing are evolving around silicon photonics.

FormFactor already plays a significant role in the implementation of silicon photonics technology. This illustrates how we participate in solving the challenges of wafer test long before a new technology goes into mass production.

Learn more about silicon photonicsArtificial Intelligence Processors

Artificial Intelligence (AI), once the stuff of science fiction movies, now manifests in various forms—from personal assistants in cell phones to tailored movie recommendations and drone-based pipeline inspections, among others.

AI’s neural networks learn much like their biological counterparts, relying on examples and repetition rather than the sequential logic of standard computer programming. These networks consist of large concentrations of interconnected nodes, each representing the equivalent of a single neuron. Essentially, each node acts as an independent algorithm, exchanging data with its peers as the network gains intelligence and arrives at solutions.

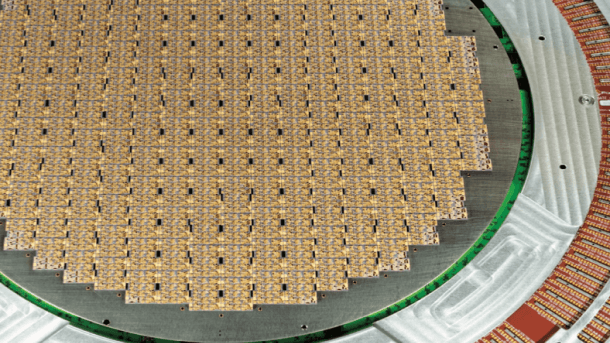

In general, this process requires voluminous amounts of computing power to continually model the behavior of each node during each training cycle. This makes AI’s machine learning an ideal candidate for massive parallel processing. Massive parallelism once existed exclusively in the realm of supercomputers, but recent advances in chip technology now allow it to reside on a single IC substrate that integrates billions of transistors.

As AI continues its integration into new generations of silicon, FormFactor remains committed to providing wafer probe solutions that contribute to its development.

Learn more about artificial intelligenceCPU / GPU / Logic

The explosion of data generated by internet traffic and a myriad of other sources is demanding faster and faster server processors and artificial intelligence for real-time decision-making capability. With the decline of Moore’s Law, advanced processors now turn to next-generation advanced packaging techniques to sustain the pace of innovation demanded by HPC applications. Heterogenous integration ties processors, memory, I/O, logic, and interposers together with bumps, pillars, through-silicon vias, and other elements.

Wearables, smart phones, and Internet of Things (IOT) also drive the development of small, high performance, long battery life devices, and utilize wire bond, flip-chip, and wafer-level packaging in smaller and smaller form factors.

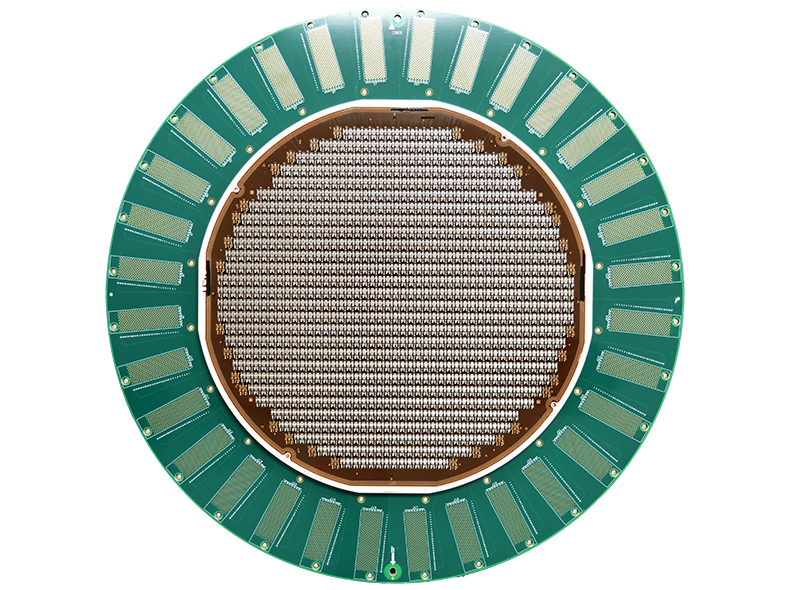

Advanced package technologies, very large and very small dies, and increasing probe pad density create new wafer probing challenges. FormFactor leads the industry in the breadth of advanced, MEMS-based probe card solutions to these challenges, able to test thousands of dies simultaneously, with hundreds of thousands of parallel probes, and even probing directly on 3D contact elements.

Learn more about logic/SOCMemory

Our interconnected society generates exponentially increasing amounts of data, with multiple zettabytes (each zettabyte is approximately 10^21 bytes) per year in internet traffic. Data centers, mobile devices such as cellphones, smart IoT devices, and more, all need more DRAM and flash memory than ever before. Higher-density, faster flash and DRAM memory such as HBM (high bandwidth memory) leverage advanced packaging techniques, sometimes stacking over a hundred die in a single IC package.

As the memory IC market continues to advance and expand, semiconductor manufacturers face the complex challenges of high parallelism and full-wafer contact testing. FormFactor’s range of high-performance wafer test solutions help chip suppliers achieve yield optimization, lower cost of test, and faster time-to-market for today’s advanced memory devices.

Learn More about memory